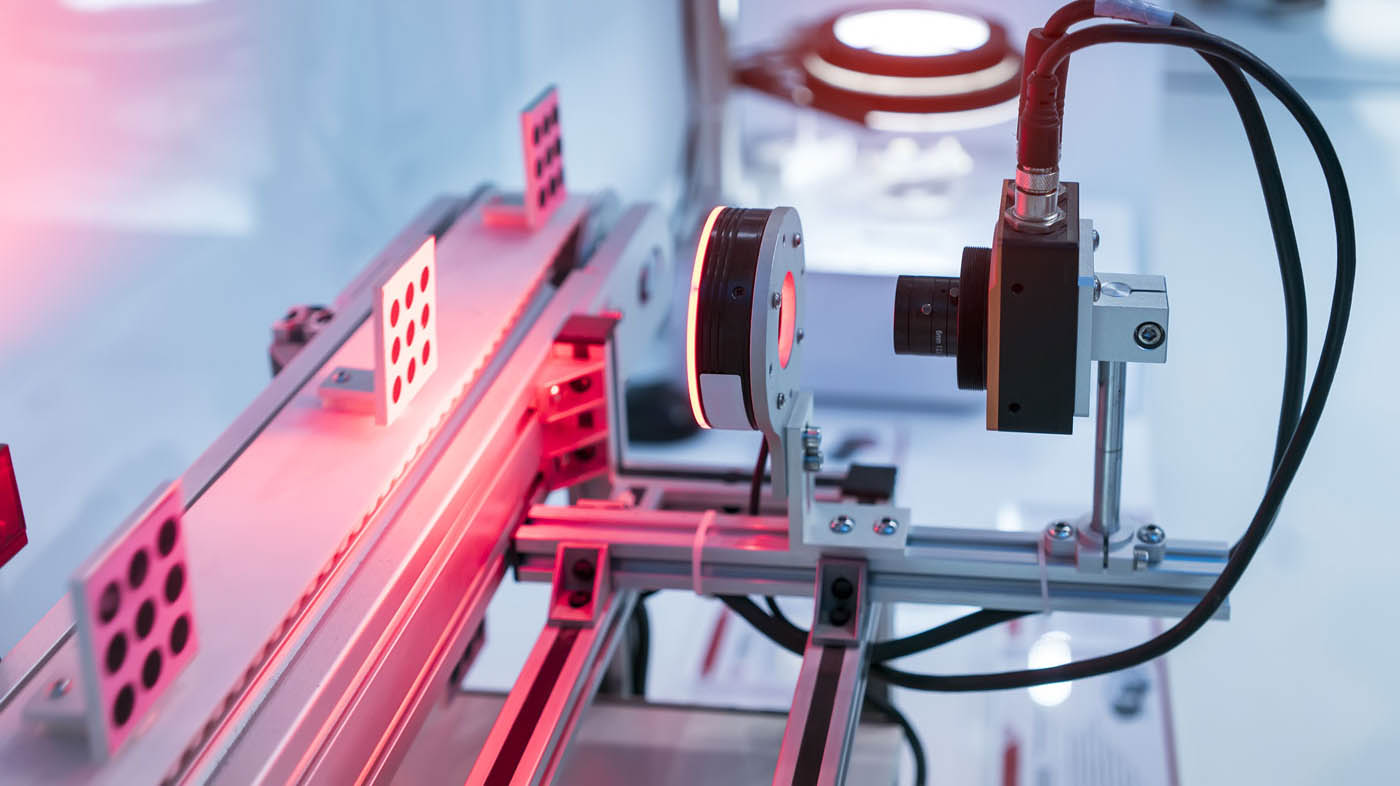

MoonVision SurfaceScanner

Industrial quality inspection of surfaces

Boost your quality management with the MoonVision SurfaceScanner. Defects on different surfaces are visually detected and differentiated fully automatically. The results are ideal products and significantly shortened quality inspections.

MoonVision WoodScanner

Automated surface inspection of wood

Determine precisely and automate the quality of logs before you process them. The MoonVision software uses visual data from cameras to check - whether their quality characteristics are fulfilled and which areas can be used for which applications.

MoonVision PaintScanner

Defect detection on painted surfaces

Use the MoonVision PaintScanner to automatically inspect painted surfaces for defects and quality properties. By using visual data generated by cameras, you will be informed at an early stage whether your quality characteristics have been met and/or whether there is a need for action.

MoonVision WeldScanner

Weld seam inspection & measurement

Reduce the time for measuring weld seams (e.g. according to DIN EN 17637) to less than one second! The MoonVision software automatically and precisely distinguishes the weld from the workpiece. Using a camera the system measures whether the result of the welding process fulfills your quality requirements. Different seam types are recognized and taken into account.

MoonVision AssemblyControl

Digital assembly line inspection

With MoonVision AssemblyControl, you have a tool set for manufacturing at your disposal with which individually manufactured components can be automatically checked for their composition, positioning and alignment. On request, a target/actual comparison with your existing data sources can also be carried out. Customers benefit from a stable and reliable quality check in their production process and significantly shortened lead times.